Cigarette Filter Fiber Study

Do Cigarette Filters Grow the Morgellons Artifacts?

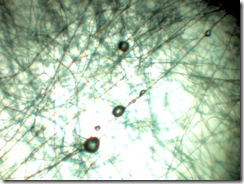

After reading the article below, and with other tests I’ve conducted, I wondered if culturing the cotton, filter part of the cigarette would cause the Morgellons and other artifacts to be seen?

From a brand new pack of unopened cigarettes, I took one out and cut the end filter with sterile scissors over a Petri Dish with potato dextrose agar.

These photos below represent my findings:

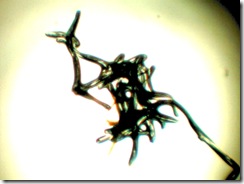

The Filter Photos, at 100x, Day 1:

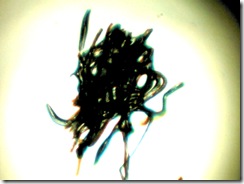

Day 2:

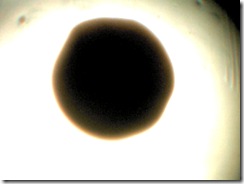

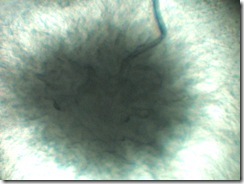

Day 5:

So far, we have seen where certain red wines, bathroom tissues and q-tips grow the same artifacts and according to the article below; all cigarette filters are made the same and all should culture the Morgellons artifacts:

Cigarettes with defective filters marketed for 40 years: what Philip Morris never told smokers

"Background: More than 90% of the cigarettes sold worldwide have a filter. Nearly all filters consist of a rod of numerous ( > 12 000) plastic-like cellulose acetate fibers. During high speed cigarette manufacturing procedures, fragments of cellulose acetate that form the mouthpiece of a filter rod become separated from the filter at the end face. The cut surface of the filter of nearly all cigarettes has these fragments. In smoking a cigarette in the usual manner, some of these fragments are released during puffing. In addition to the cellulose acetate fragments, carbon particles are released also from some cigarette brands that have a charcoal filter. Cigarettes with filters that release cellulose acetate or carbon particles during normal smoking conditions are defective.

The term "fall-out" was defined in 1985 laboratory protocols of Philip Morris, Inc. as "loose fibers (or particles) that are drawn out of the filter during puffing of the cigarette".

Our analysis of the "fall-out" tests results presented in the 61 "fall-out" documents showed that filter fibers and carbon particles were discharged from the filters of ALL types of cigarettes tested.

Conclusions: We have shown that: (a) the filter of today’s cigarette is defective; (b) Philip Morris, Inc has known of this filter defect for more than 40 years; (c) the existence of this filter defect has been confirmed by others in independent studies; (d) many methods exist to prevent and correct the filter defect, but have not been implemented; and (e) results of investigations substantiating defective filters have been concealed from the smoker and the health community. The tobacco industry has been negligent in not performing toxicological examinations and other studies to assess the human health risks associated with regularly ingesting and inhaling non-degradable, toxin coated cellulose acetate fragments and carbon microparticles and possibly other components that are released from conventional cigarette filters during normal smoking. The rationale for harm assessment is supported by the results of consumer surveys that have shown that the ingestion or inhalation of cigarette filter fibers are a health concern to nearly all smokers.

"All cigarette filters can be shown to transmit particles to the smoker. The human lung free passageways are a thousand times, yea ten thousand times, larger than particles which may pass through them. This goes for carbon, tobacco, sand, clay, lint [fibers, threads, cotton, cellulose] and all similar impurities."

In 1993 Cigarette filter fibers identified in the lungs of patients with cancer is reported. In 1998 Inhaled cellulosic and plastic fibers found in human lungs. 1998 US patent No. 5,738,115 awarded to Hauni AG for "decontaminating" cigarette filters.

1998 Borowicz and colleagues report results of tests in which cellulose acetate filter fibers and particles are recovered from mouth washes of all smokers and for all cigarettes tested.

Viewing the white face of the cigarette filter with the naked eye and compression of the filter column with the fingers would suggest that the filter is made of a sponge-like material. However, opening the cigarette filter, by cutting it lengthwise with a razor, reveals that it consists of a fibrous mass. Spreading apart the matrix reveals some of the more than 12 000 white fibers. Microscopically, these fibers are Y shaped and contain the delustrant titanium dioxide. The fibers are made of cellulose acetate, a synthetic plastic-like substance used commonly for photographic films. A plasticiser, triacetin (glycerol triacetate), is applied to bond the fibers.

During the high speed multi-step cigarette manufacturing procedures, cellulose acetate filter fragments break from the filter. Moreover, charcoal granules are released from cigarettes with certain types of charcoal filters. With a hand held magnifying glass, some of these black specks of charcoal are visible on the white filter face.

Likewise, we know that: "fragments of plastic fibers, such as cellulose acetate fibers, forming part of mouthpieces of filter cigarettes or like rod-shaped smokers’ products tend to become separated from the respective filter mouthpieces at the end faces which develop in response to the making of cuts across filter rod sections of double unit length between pairs of plain cigarettes to obtain filter cigarettes of unit length." It is emphasised that: "The fiber contamination of the mouthpiece occurs in spite of the partial bonding of the neighboring fibers to each other by resorting to suitable plasticizers." These quotations are from 1997 and 1998 US patents awarded to Hauni Maschinenbau AG.13, 14 Hauni AG, with its eight divisions of companies, has an established reputation as the world’s top manufacturer of high speed machinery for making, packaging, and analysing cigarettes.

Cigarettes have defective filters if cellulose acetate filter fragments are released from the filter by puffing. In 1995, an executive directive declared that tobacco companies: "are well advised to strongly urge filter manufacturers to explore ways of producing fiber-free filters. Cellulose acetate fibers, in the smallest concentrations, must not be found in lungs. This is true even if there is little likelihood for their contributing to the formation of lung cancer and to disease type inflammatory changes."

Repetitive tests showed that carbon particles were released. In a 1970 test of: "Fallout of cigarette filter material" (10 cigarettes, 5 puffs) carbon particles were sized and enumerated.30 The results were as follows: size range 5 µm (n = 20 particles), 6–10 µm (n = 38), 11–20 µm (n = 22), and 21–30 µm (n = 14), etc. A total of 124 carbon particles was recorded.

We reviewed the test results in all of carbon "fall-out" papers. This review showed that carbon particles were released from all cigarettes tested. Noteworthy is that, in some studies, the particles released from cigarette filters were described as: "… too numerous to count".

Dr Farone has acknowledged that Philip Morris, Inc was concerned as to the possible health risks associated with inhaling filter fibers and carbon particles. Dr Farone reported to us that a claim made by Philip Morris, Inc that the filter fibers were too big to get into the lung was based upon an aerodynamic diameter concept only, and emphasised that the concept was an unproven hypothesis. Some of the fibers that "fall-out" of the filter are likely to be deposited in the mouth and upper airways. However, given the known frequency with which most people smoke cigarettes, Dr Farone asserted that it is inevitable that some of the cellulose acetate fibers would be inhaled.

One of the primary objectives in applying a plasticiser is to bind the fibers. The plasticiser, however, is applied before the cigarette filter is cut and other cigarette manufacturing processes. Thus, the bonding agent may curtail but would not eliminate the formation nor the release of filter fiber fragments.

Filter contamination not disclosed by Philip Morris, Inc

Having established that Philip Morris, Inc. knew for approximately 40 years that cigarette filters released cellulose acetate fibers and carbon particles.

Also, there were no reports from Phillip Morris, Inc that addressed the release of fibers, carbon or other filter elements of the cigarette filters in any of the papers presented during the last 37 years at the CORESTA meetings or special symposia.

The absence of papers from Phillip Morris, Inc examining these issues is remarkable in light of the fact that nearly all cigarettes manufactured during the past two decades have a cellulose acetate filter.

Our search of multiple databases failed to locate documents presenting the results of toxicology studies of fibers and particles that are known to be discharged from cigarette filers during normal smoking conditions. At a minimum, we expected to find laboratory notebooks or at least photocopies of selected notebook pages. Not a single page was found.

Also noted in these two patents is that in the manufacturing of cigarettes, considerable quantities of "fragmentised" tobacco particles are collected and reintroduced into cigarette making machines. Both patents declare that: "This is not advisable as the cellulose acetate fibers would be placed in the tobacco column." The cellulose acetate fibers in the tobacco column are burned and would emit additional toxins into mainstream smoke.

Collectively, our investigations have identified diverse types defective filters. These include filters that discharge various filter elements, including fibers (for example, cellulose acetate, glass and asbestos) and particles (for example, charcoal).

A recent study has assessed consumers’ knowledge and beliefs about the safety of cigarette filters. In this survey, participants were asked: "If cigarette fibers become loose, and the cigarette companies are aware of this, do you think that they have an obligation to warn the public about this?" All smokers and former smokers in this survey responded "yes".

Philip Morris, Inc has known and concealed for approximately 40 years that fibers and particles "fall-out" of the filter of cigarettes during smoking. Other companies have assessed also the discharge of filter fibers. In addressing this filter defect, the tobacco industry’s response has been variable, ranging from denial of the discharge of filter fibers to the development of innovative technologies for correcting and preventing the problem. Consumers have not been informed of the filter defect. Further, there is no indication that existing corrective technologies and invention have been uniformly implemented. Summarily, the tobacco industry has been: (a) derelict in concealing information of filter defects; (b) negligent in implementing technologies available to prevent or reduce the emission of filter elements; and (c) wrongful in not investigating the toxicology and harm associated with defective filters of today’s cigarettes that are being marketed worldwide.

Tobacco companies bare the burden of performing the toxicology studies necessary to assess the human health risks of the defective filters and, specifically, the dangers associated with the daily inhalation and ingestion of the substances discharged from the filter during normal smoking. All consumers, including smokers, have the right to be fully informed of product defects and the potential risks that they impose so that they can make an educated decision in selecting their cigarette purchases.

The inhalation and/or ingestion of toxin coated plastic fibers and carbon granules released from contaminated and defective filters is not intended to be part of the smoking experience. The filter is intended to reduce exposure to cigarette smoke toxins—any elements from the cigarette filter that are likely to be puffed into the lung must be recognized as pollutants. For a company to knowingly and willfully withhold this information from consumers about the known contamination of cigarette filters, as Philip Morris, Inc had done in the past and continues to do even today, is wrong." [1]

References:

[1].

http://tobaccocontrol.bmj.com/cgi/content/full/11/suppl_1/i51

4 Comments »

Leave a comment

-

Recent

- Morgellons Artifacts Found in Rainwater – Part 1

- Morgellons Researchers

- Morgellons Disease Sufferers Growing Weary in the Wait

- Morgellons Progression Study

- How Morgellons Is Formed

- Morgellons Is Partially the Frog Fungus

- Morgellons Is Zoonotic

- Morgellons ‘Fibers’ Turn Into Spheres

- Our Morgellons Spheres

- The Morgellons "Spaceships"

- A Lot of Fiber in our Diet?

- Cigarette Filter Fiber Study

-

Links

-

Archives

- April 2010 (3)

- March 2010 (5)

- November 2009 (6)

- October 2009 (13)

- September 2009 (4)

- June 2009 (13)

-

Categories

-

RSS

Entries RSS

Comments RSS

[…] See a strange post: Cigarette Filter Fiber Study « Morgellons Researchers […]

Pingback by Cigarette Filter Fiber Study « Morgellons Researchers - Health Articles A to Z | November 18, 2009 |

[…] This post was mentioned on Twitter by Steve Topol, John Brigiotta. John Brigiotta said: Cigarette Filter Fiber Study « Morgellons Researchers http://bit.ly/1V7AOp […]

Pingback by Tweets that mention Cigarette Filter Fiber Study « Morgellons Researchers -- Topsy.com | November 19, 2009 |

I am frequently searching for brand-new blogposts in the net about this theme. Thankz!

Sometimes it’s really that simple, isn’t it? I feel a little stupid for not thinking of this myself/earlier, though.